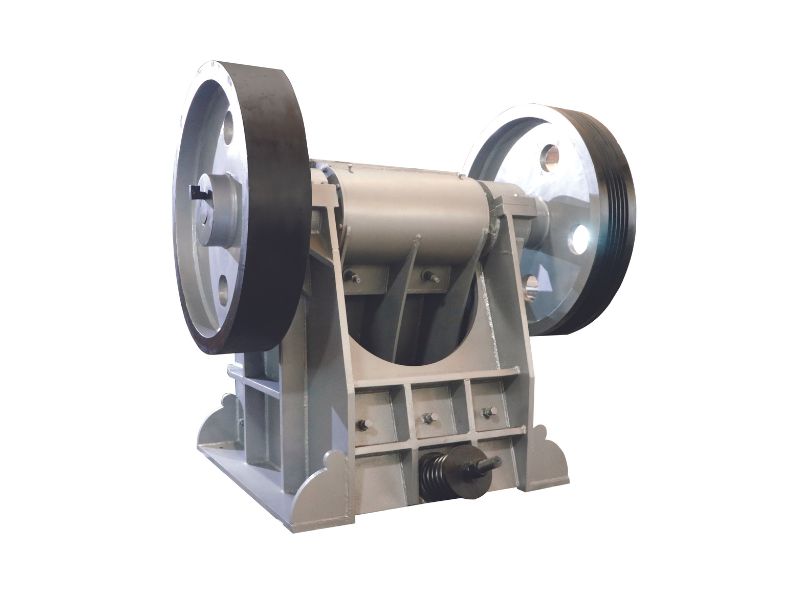

Jaw crusher machine is a robust industrial tool specifically designed to crush hard slag materials with efficiency. Its primary function is to reduce large chunks of slag into smaller, manageable fragments suitable for further processing. Featuring a sturdy frame and powerful jaws, this machine exerts immense pressure on the slag, breaking it down effectively. The jaw crusher’s design incorporates a fixed jaw and a movable jaw, providing a crushing mechanism that ensures thorough fragmentation. With customizable settings, operators can adjust the machine to achieve the desired size and consistency of crushed slag particles. Built with durability in mind, the jaw crusher is engineered to withstand the abrasive nature of hard slag materials, ensuring long-term reliability. Safety features like overload protection and emergency stops enhance the operational safety of the jaw crusher machine. Its versatile design allows it to be used in various industrial settings, including mining, metallurgy, and construction, where hard slag crushing is required. Regular maintenance and lubrication are essential to keep the jaw crusher machine in optimal working condition, maximizing its lifespan and efficiency. Overall, the jaw crusher machine stands as a crucial asset in industrial operations, efficiently transforming hard slag into manageable fragments for downstream processes.

The roller crusher machine, tailored for crushing slag into 0-20 mm particles, operates with precision to achieve desired particle size reduction. Featuring sturdy rotor and a powerful motor, this machine exerts high pressure on the slag material to effectively break it down into smaller fragments. Its adjustable gap setting mechanism allows for precise control over the final particle size, ensuring uniformity in the crushed output. Equipped with robust crushing blades, the roller crusher efficiently pulverizes slag, transforming it into fine particles suitable for various industrial applications. The roller crusher machine’s compact design and efficient crushing action make it ideal for processing slag in confined spaces or on-site applications. Integrated safety features, such as emergency stop buttons and safety guards, ensure operator protection during operation. With its high throughput capacity, this machine effectively handles large volumes of slag, making it suitable for heavy-duty industrial operations. Versatile in its applications, the roller crusher machine can also crush other materials besides slag, offering flexibility in processing various materials. From steel plants to recycling facilities, the roller crusher machine serves as a reliable solution for transforming slag into finely crushed particles ready for further processing or reuse.

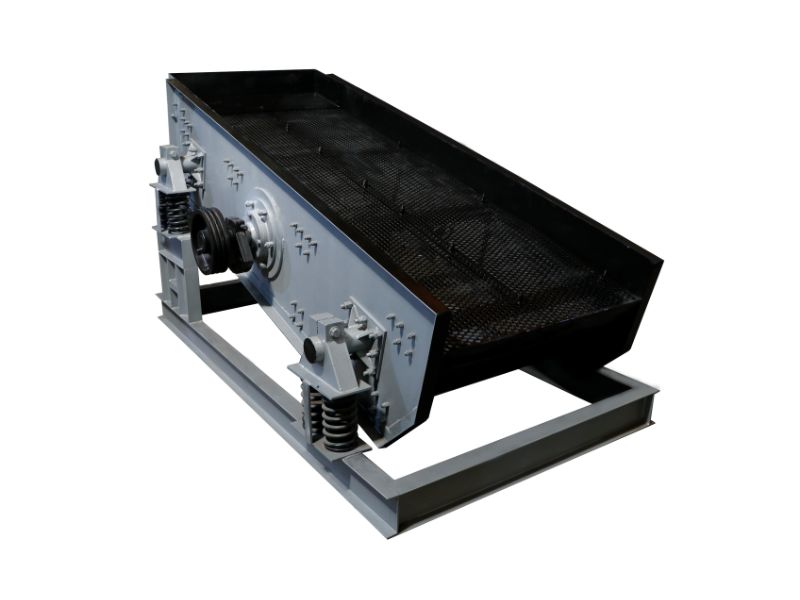

A vibrating screen machine is designed to segregate materials according to their size through vibration. Utilizing a series of vibrating decks or screens, this machine efficiently separates particles into different size fractions. Its high-frequency vibration ensures thorough screening, allowing for precise segregation of materials based on size criteria. The vibrating screen’s design includes mesh panels or perforated plates, which facilitate the passage of particles of specific sizes while retaining larger ones. Adjustable settings enable operators to customize the screening process, ensuring optimal segregation of materials according to their size requirements. With its robust construction and durable components, the vibrating screen machine can withstand the rigors of continuous operation in various industrial settings. Safety features such as protective covers and emergency stops enhance the operational safety of the vibrating screen machine. Its compact design and efficient screening capabilities make it suitable for a wide range of applications, including mining, construction, and recycling. Regular maintenance and cleaning are essential to ensure the smooth operation and longevity of the vibrating screen machine. Overall, the vibrating screen machine plays a crucial role in industrial processes by efficiently segregating materials according to size, thereby enhancing productivity and quality control.

The magnetic separator machine, engineered to separate magnetic particles from slag, employs a high gauss power magnetic drum to achieve efficient separation. With its powerful magnetic field, this machine effectively attracts and captures magnetic materials, such as iron and steel, from the slag mixture. The high gauss power ensures strong magnetic force, enabling thorough separation even of fine magnetic particles from the slag. Equipped with a rotating drum, the magnetic separator machine facilitates continuous operation, ensuring a steady flow of separated materials. Advanced magnetic technology ensures reliable performance, delivering consistent results in separating magnetic materials from slag. The magnetic separator machine’s robust construction and durable components make it suitable for handling heavy-duty industrial applications. Safety features such as overload protection and emergency stop systems ensure operator safety during operation and maintenance. From steel mills to recycling plants, the magnetic separator machine serves as a vital tool in efficiently recovering magnetic materials from slag, contributing to resource conservation and recycling efforts.

The grinding mill machine, specifically engineered for separating stuck slag from magnetic materials, utilizes a powerful hammering action to achieve efficient separation. Its robust construction and high-torque motor enable the machine to effectively break down and pulverize the stubborn slag particles. Equipped with specialized hammers, this machine ensures thorough grinding and separation of the slag from the magnetic material. Advanced magnetic separation technology integrated into the grinding mill enables the efficient extraction of magnetic material from the slag mixture. With its rapid throughput capacity, the machine efficiently processes large volumes of material, increasing productivity in industrial operations. The grinding mill machine is equipped with safety measures to safeguard operators and maintain a secure working environment during operation. Its versatility extends beyond slag separation, as it can also be used for various grinding applications in different industries. The grinding mill machine stands as a reliable solution for industries seeking efficient and cost-effective methods for separating slag from magnetic materials.