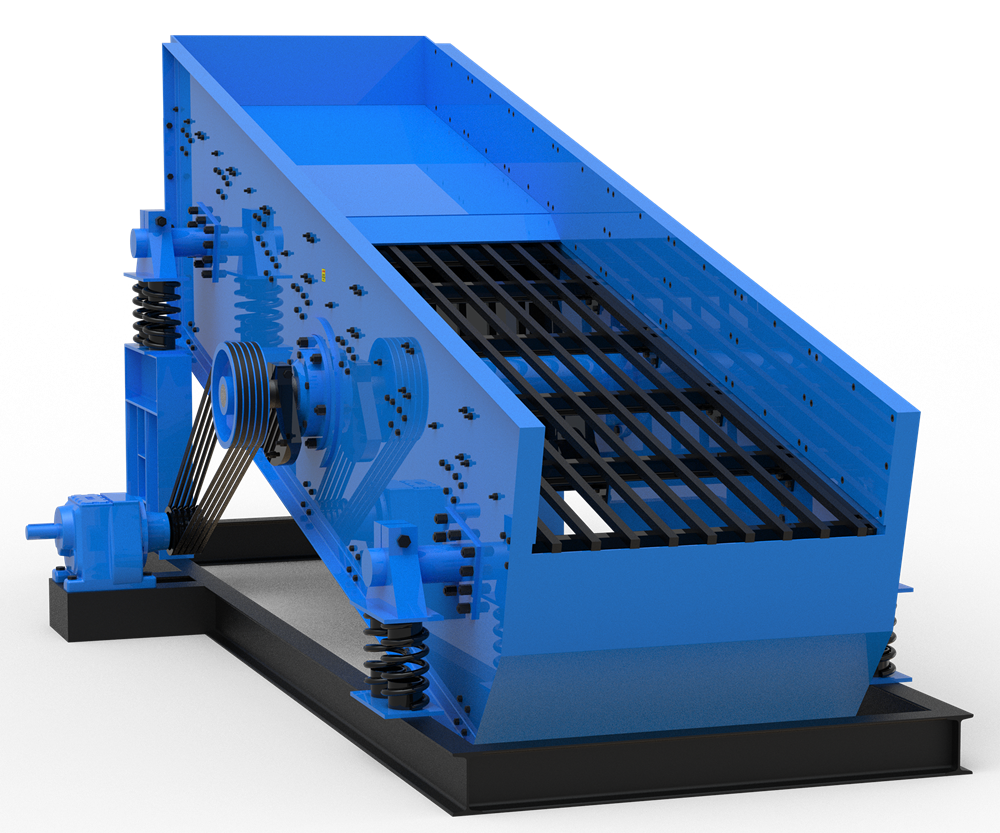

Vibrating Grizzly Feeder

The Vibrating Grizzly Feeder (VGF) is a heavy-duty mechanical feeder designed to feed large, coarse materials consistently and efficiently into primary crushers. It combines a powerful vibrating mechanism with a grizzly bar section that pre-screens and separates fines from the feed material – thereby reducing crusher load and increasing productivity.

At Bhupindra Machines Pvt. Ltd., we design and manufacture custom-engineered Vibrating Grizzly Feeders to suit the harsh demands of slag handling, mining, aggregate, and steel industries

Key Features

- Heavy-duty, all-welded steel construction for rugged performance.

- Integrated grizzly section for pre-screening of fines and separation of oversized materials.

- Adjustable vibration amplitude and frequency to suit different material properties.

- High wear-resistant liners and grizzly bars for longer life.

- Available with motorized or mechanical excitation

- Custom-built design to match crusher capacity and conveyor setup.

- Suitable for feeding primary jaw crushers, impact crushers, and hammer mills.

Applications & Industries

Our Vibrating Grizzly Feeders are widely used in:

- Slag Crusher Plants (Steel Furnace Slag / Foundry Slag)

- Stone Crushing Plants

- Mining and Quarrying

- Recycling and Scrap Handling

- Coal Handling Plants

- Cement Industry

- Iron Ore & Mineral Processing

- Aggregate Production

- Thermal Power Stations

They are essential for handling abrasive, high-impact material streams in continuous-duty environments.

Vibrating Grizzly Feeder

Our Vibrating Grizzly Feeders are built with heavy-duty steel construction and integrated grizzly sections for pre-screening fines and separating oversized materials. With adjustable vibration settings, wear-resistant liners, and custom-built designs, they deliver long life and reliable performance while feeding primary crushers and conveyors.

Applications & Industries

Widely used in slag crusher plants, stone crushing, mining, quarrying, recycling, coal handling, cement, iron ore processing, aggregate production, and thermal power plants, these feeders are ideal for handling abrasive, high-impact materials in continuous-duty operations. Their robust design ensures consistent performance and reduced downtime.

Benefits of Using a Vibrating Grizzly Feeder

- Protects Crushers: By removing fines and small stones, VGFs prevent overloading and wear of primary crushers.

- Improves Efficiency: Reduces crusher power consumption and increases throughput.

- Saves Maintenance Time: Minimizes blockages and reduces downtime for cleaning or maintenance.

- Built for Tough Conditions: Handles large, heavy, abrasive materials like furnace slag, rocks, and crushed metal.

- Custom Engineering: Every VGF is designed based on material size, flow rate, and plant layout.

FAQs – Vibrating Screen For Slag And Stone Crusher Plants

It feeds bulk material into crushers while pre-screening fines and separating out smaller particles to protect and improve the efficiency of the crushing system.

Yes. Our feeders are specially designed to handle hot, abrasive slag material and large steel waste in crushing plants.

Vibration is typically generated by unbalanced motors or exciter gearboxes, depending on design.

Yes. We offer custom grizzly bar spacing to suit different material types and output requirements.

Yes, but with certain modifications. In such cases, self-cleaning grizzly bars or vibratory adjustments can be incorporated.